Observations

of a first time boat builder

by Charles

Hall I've just completed building my first boat, a stitch-and-glue sailing dinghy

built from plans. Building it was a lot of fun, and I learned so much in the

process. You'd think after reading Messing About in Boats for a few years

the actual building of a boat myself would hold few surprises -- WRONG.

No, I didn't learn how to get a perfect varnish finish, or how to cast bronze

hardware. I learned simpler, more basic stuff. Just things you never encounter

outside of building a boat, no matter how many bookcases you build for the den,

or how big that garden shed is you built. And this was just an 11-foot dinghy…

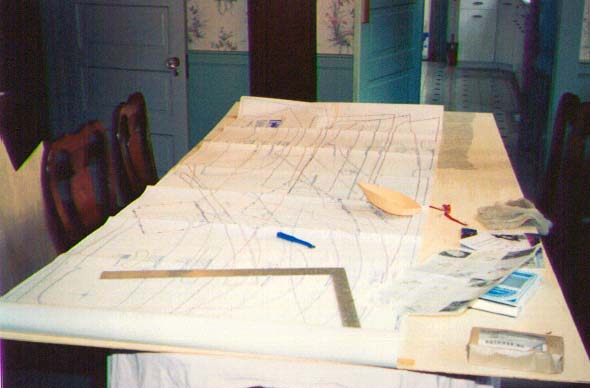

Lesson #1 - Full-size Patterns vs. Lofting

The Loonfeather plans come with full-size templates for all the pieces

of the boat. In fact, they're all on a single piece of paper! Now imagine how tricky this first step would be if you had to loft the plans

yourself from a set of measurements? Lofting is a two-day class at my local

maritime museum. In my opinion, a first time boatbuilder working alone should

avoid lofting. A goof here will cost you dearly.

Lesson #2 - Thin plywood cuts like butter

Now I've done my share of work with plywood, but I was really surprised at

how easy it is to work with ¼" plywood. I guess I'm more accustomed to thicker

plywood. There's not much call for ¼" bookshelves :-) This stuff cuts like butter.

Put a nice hollow-ground blade in your little saber saw and you won't even have

to sand it (so I'm not a perfectionist). My saber saw is the cheapest variable-speed

saw I could buy, and it's ten years old. Worked perfect. A fancier, heavier

saw would not have been as good. The fancy scroll features some have aren't

useful here, and light weight is.

Lesson #3 - There are no right angles

There are no right angles. Think about it. There are no right angles. Your

square, your framing square, your combination square - put'em away. There are

hardly even any straight edges! The most useful tool you can have is a long

thin springy bit of wood (known as a "batten") to lay down on your plywood and bend into

a smooth ("fair") shape. Something to smoothly connect-the-dots of your pattern-marks.

And as someone else once said, if you find a nice batten, hang on to it. You'd

be surprised how hard it is to find a nice knot-free strip of wood eleven feet

long.

Lesson #4 - There's nothing to measure

Your tape measure has a certain utility, but by and large this is a free-hand

project. If it looks right, it is. In most cases there's just no way to measure

what you're looking at. See Lesson #3. So put away your tape measure and your

yard stick.

Lesson #5 - It really is an instant boat

The initial cutting of boat parts from plywood is dramatic and fast-moving.

The day you wire it all together and it takes on a "boat" shape is truly exciting.

You've built a boat!! Your friends will be amazed.

Lesson #6 - It's not really an instant boat

Have you ever driven past a home construction site every day for a while?

You'll see lots of activity at first, but, no progress - just a foundation.

Then suddenly, between when you drove by in the morning and when you pass by

that evening, there's a house! The studs are up, the roof trusses are in place,

roofers show up in no time. You'll have to meet the new neighbors soon… but

no you won't. There's a surprisingly long period between the house taking shape

and the last carpenter walking out the front door. What happened? It's all those

pesky little pieces on the inside that slowed them down. And guess what? It's

the same on your boat!

I did the first phase of my boat under a tree in the backyard, I figured

I'd have it fiberglassed and water-proof in no time. Well, some other stuff

intervened, but the last phase of the boat seemed to take forever - it was a

good thing I had a house with a basement by then.

Lesson #7 - All boat building projects get interrupted

In between the first few weeks of my boat project and the last, there was

a three-year hiatus. We moved to a new house, I changed jobs, my wife changed

jobs, there was a death in the family, hurricane Fran hit, etc. At first, I

thought it was just me; but then I noticed lots of other telling phrases in

letters and articles where other folks had the same thing happen. Huge, long

time-outs from their boatbuilding. It must be an immutable fact of nautical

life.

Lesson #8 - Never let your project take too long

When I began my boat, it was the most ideal boat on earth. It had a novel

seating arrangement, it could be car-topped, you could sail it, row it, sleep

in it. It was perfect. Well, after three years I realized the most comfortable

seats are in kayaks, my back is so bad I'd never be able to car-top it, I no

longer wanted to row anything and I'm not going boat-camping. Times had changed.

My life has changed. Don't let your project take too long.

Lesson #9 - It's not going to be perfect

As the boat nears completion, you begin to realize it won't be perfect. After

all, this is your first boat. No one is going look at it and say "Which

store did you buy that boat from?". Little imperfections creep into any big

project. And even a small boat can be a big project. There are many opportunities

to screw up. The big screw-ups you tear apart and fix, but if you try to fix

all the little screw-ups you'll never finish the boat. I guarantee you that

most unfinished boats stop here, when the builder realizes it won't be as perfect

as he dreamed it would be.

Lesson #10 - It's going to be good enough

The Loonfeather's designer made some marvelous design decisions. There are

many, many points where a roughly cut free-hand edge is capped by a smoothly

curved bit of edging. Or where that hard-to-fit triangular bit in the bow can

be installed at any angle that fits the shape you cut. Gradually, you begin

to see that your screw-ups won't be so obvious. In fact, you'll forget a lot

of them ever happened.

The long gunwales on the Loonfeather would be just a raw ¼" plywood edge,

an edge you had to cut free-hand. But the plans call for two thin strips of

pine that you glue and twist along the edge. Then you can come back and sand

the plywood down to meet the smooth pine edging. It really looks great.

But now, you realize that you need a special tool…

Lesson #11 - Buy an electric sander

I don't sand my projects much. Just take off the splinters and get a good

coat of paint on it. But on a boat, every ripple in a curved edge stands out.

So, unless you want to sand by hand for the rest of your life, buy a sander.

Not some sissy-little vibrating thing, I mean a belt-sander. We're talking "wood

removal" here. The one I bought takes 3" belts, I guess it's the smallest model

they make. That's the kind you want: small and light.

Lesson #12 - It going to look pretty good

Even with my limited skills, the design of the boat will keep it from looking

too bad. In fact, it looks pretty good. At ten-feet you'd look at it and think

I'm a master carpenter. Up close, well, you won't get splinters in your hand.

My next boat…

Now that I'm an expert (he-he) I know exactly what the next boat will be.

First it'll be small enough not to take over the entire basement in case it

takes a long time to finish. Second, I'll try to schedule enough time for it

so it doesn't take a long time to finish. There are these skin-on-frame kayak

plans from Hobbycrafts. They say it can be built in 10 hours... and it

ought to use even fewer tools! I'll let you know how it turns out.

- So much for construction -

Between the delaminating plywood and uncomfortable layout I had to give up on this boat.

I sawed it up and took most of it to the dump, keeping the nicely curved bow and stern

for some future wall-hanging. Too bad, she was pretty wasn't she?

Sept. 1998

Post Mortem

The boat came out looking fine. I borrowed a sail from some other project to

get it on the water and see how it worked. Sadly, the boat was short-lived.

Despite my satisfaction with the construction process, there were several

fatal flaws:

The boat came out looking fine. I borrowed a sail from some other project to

get it on the water and see how it worked. Sadly, the boat was short-lived.

Despite my satisfaction with the construction process, there were several

fatal flaws: