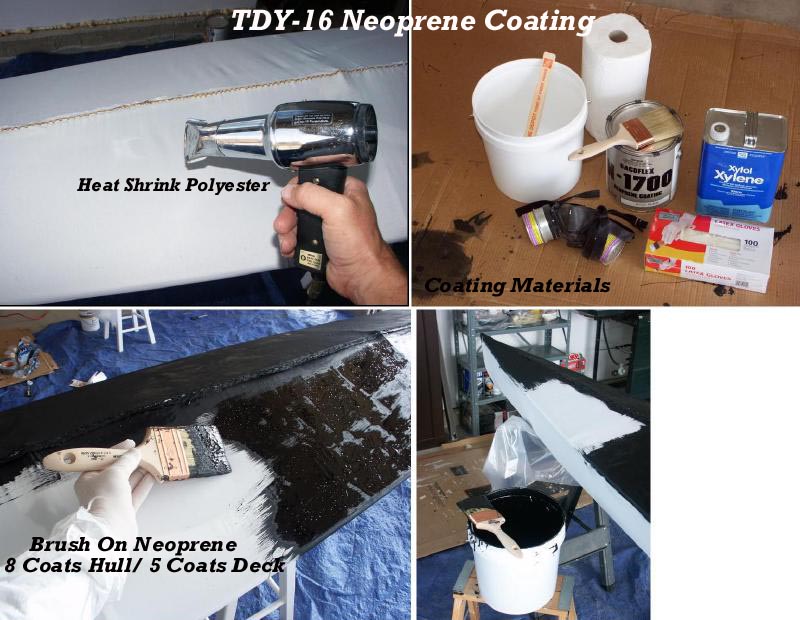

The frame is first waxed to insure that neoprene will not soak through and stick to either the aluminum or HDPE. Before coating , a heat gun is used to remove wrinkles still remaining in the skin after sewing. The first two coats of Neoprene are thinned with 10percent Zylene to insure that the neoprene will soak deeply into the polyester cloth. Subsequent coats are thinned but to a lesser degree.

Neoprene is applied with a 3 or 4 inch brush. Use short brush strokes and be sure not to brush the neoprene once it starts to glaze over. That will cause ripples in the surface. Maintain a wet edge and move quickly along the surface. Subsequent coats of neoprene can be applied every 30 minutes or so.

When the skin is removed, the inside hull will receive two additional neoprene coats. This is not necessary, but will insure complete saturation, and makes for a better looking job.

Always wear a respirator, and work in a VERY well ventilated area.

Contributors to this page: Thomas Yost (TDY), Patrick Poirier (PPR), Gerald Maroske (GUM) and Hendrik Maroske (HHM)