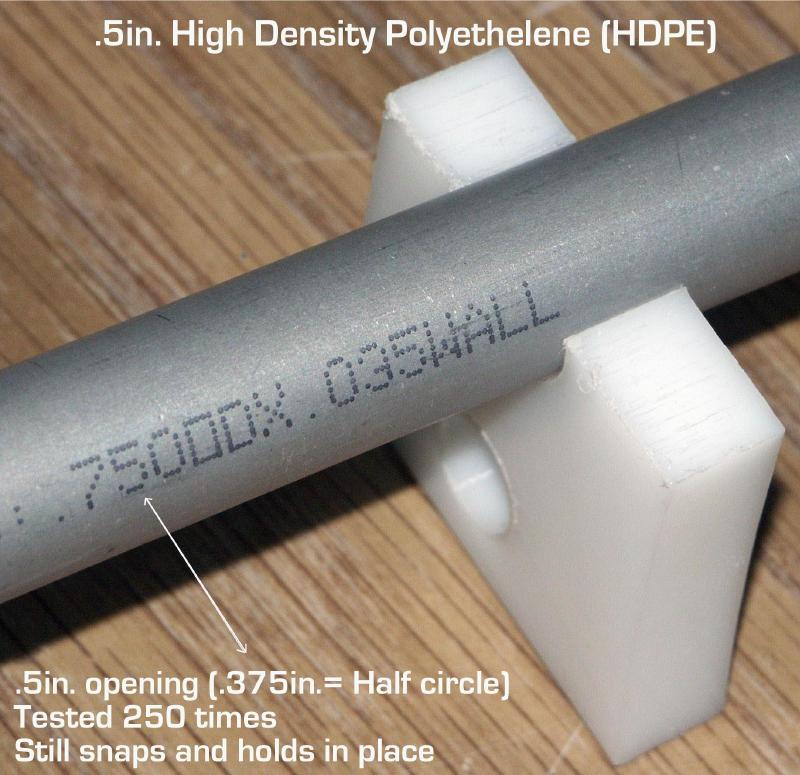

High Density Polyethelene:

Tom writes:Also attached is a photo of a test piece of HDPE that I drilled and cut to create a 1/2in opening which is 1/8in beyond the half circle (3/8in) of a 3/4in tube. I certainly wish the US would go to metric for the sake of logic and uniformity. (3/4 = 6/8 = 12/16 =.750in = and so on.)

Anyway, I tested this by "snapping" the HDPE on a 3/4in tube 250 times to see if it would fail ( no snap and hold no more). It worked fine and 250 "snaps" is a lifetime for a folder. I purchased a 4X8ft. sheet of 1/2" HDPE ($175.00 US) which is enough for a couple of boats.

This is the easiest way I know to connect tubing to a folder cross-section. Feathercraft has been using this method successfully for many years. HDPE is easy to cut, and easy to drill. In fact, it easier than working with plywood, much to my surprise. Also, I plan to lay up a fiberglass coaming for the folder.

Contributors to this page: Thomas Yost (TDY), Patrick Poirier (PPR), Gerald Maroske (GUM) and Hendrik Maroske (HHM)