My design routine begins with the gunwales. These are built at the full length of the boat. This is possible because the aluminum factory is not far from here. I make the bow and stern bulkheads and spread the gunwales apart. This only requires the angle between the gunwale and a vertical line (78 degrees), the dimensions of the stem and stern bulkheads and the frames fore and aft of the cockpit. For a better description of this read The Aleutian Kayak by Wolfgang Brinck.

The output of this action is a boat's beam, length, sheer and rigidity against vertical loads. Combined with the given height of any section, this also predefines the boat's amount of rocker. The two gunwales are designed so strong that they can accept all vertical loads that bear on the structure. This is done with two aluminum tubes and stiffening shear plates that creates an efficient and lightweight shear webbing. The next step is to set up the deck stringer and cockpit rim; now this defines a sort of a ''deck frame''. This approach's advantage is the simple building bed (you may just take some sawhorses); the aleuts also built the ''deck frame'' first. The height of the frames and the position of the stringer result out of David Zimmerlys book ''Qajaq: Kayaks of Siberia and Alaska'', page 17 (Aleut Kayak, collected on Atka Island in 1934 by M.Lantis).

If you consult an aluminum structural handbook you will find that compared to wood, aluminum is not necessarily lighter and stronger if you do not change the construction details. I added to the height of the gunwales and the height of the sheer. I designed only one stringer and placed it at about the middle of the two lower original stringers.

Resulting out of the reduction to 6 frames, the large cockpit, and all that Make-It-Foldable-Stuff there is not much left of the original design of a baidarka. Anyhow, for me it is important to realize the idea of such an old design, even if my realization of it is foldable and of aluminum.

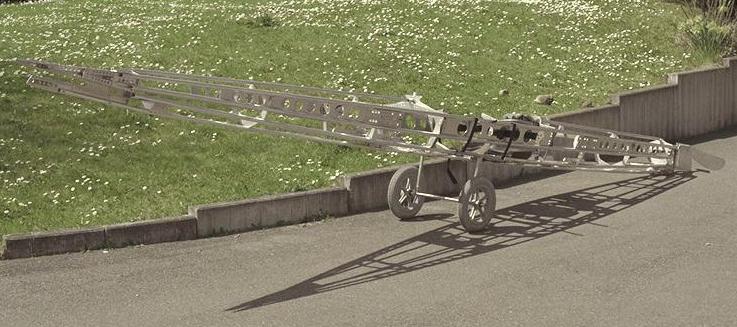

The 3-dimensional form of the boat directly results out of the bending of the gunwale tubes, constrained by the already mentioned four gunwale spreaders. Out of this I measure the dimensions of each frame. There are four frames left to make; 2 for the front and 2 for aft. Actually, I cut them out of 2mm aluminum plates. After all, I disassemble the boat and reinforce all frames. I add the tube connectors and after that, I cut all tubes apart. After cutting, the 3-d form changes a bit, because of the changed material stiffness at the position of the connectors. The boat is cut in two areas; so each stringer has three parts. One separation point is before the cockpit, and the other aft of it. At the position of maximum bending moments (the cockpit area), there is no connector that can break. The bag for the parts is about 1.7m long, 0.25m wide and 0.35m high.

Contributors to this page: Thomas Yost (TDY), Patrick Poirier (PPR), Gerald Maroske (GUM) and Hendrik Maroske (HHM)