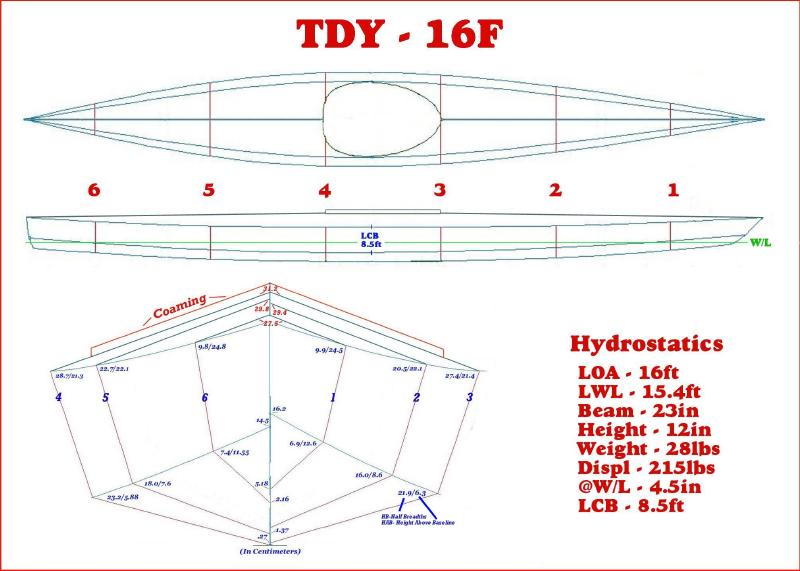

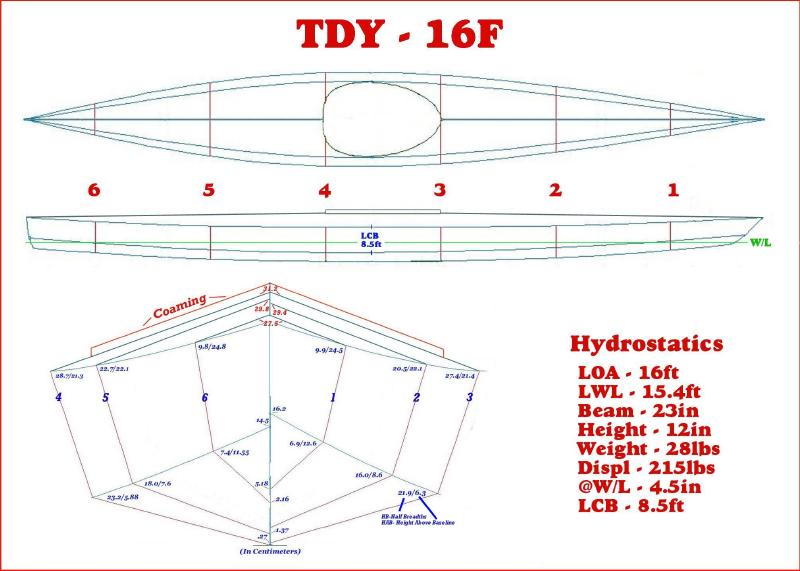

This Non-Aleut design is intended as a lightweight medium volume touring kayak. As compared to FAP-16, it features a peaked deck to improve interior room for the paddler as well as more storage space. It utilizes thinner walled tubing (3/4" X .035) and six cross sections ( FAP-16 has seven) to reduce weight. The cross sections, coaming, and footbrace are made from HDPE. Finished weight is approx. 26 lbs.

The skin is a sewn, one-piece Polyester (9 oz.) design, and is coated with Neoprene/Hypalon. The hull is covered with eight coats of neoprene, while the deck is covered with five coats neoprene and three coats Hypalon. Neoprene is a bit easier to apply than Hypalon. It cures quicker, and is more durable. Hypalon has the advantage of being easier to fold, and is available in many different colors.

The following pages highlight only those construction details not included with, or that differ from FAP-16:

Stem, Stern and Frame

FAP-16 and TDY-16 Frames

TDY-16 Frame

Coaming Details

The HDPE coaming is comprised of 1/4" baseplate, 1/2" coaming, and 1/8" coaming lip.

Machine screws are used to provide a secure coaming attachment.

Polyester Skin (9oz.)

The one-piece Polyester skin is sewn with nylon squidding line.

The deckridge and stem/stern are cut (seared)

with a propane cutting blade prior to sewing. This process

assures a hard edge that will not separate.

The deckridge will be cut open for the installation of lacing or zippers.

Neoprene

The frame is first waxed to insure that neoprene will

not soak through and stick to either the aluminum or HDPE.

Before coating , a heat gun is used to remove wrinkles

still remaining in the skin after sewing.

The first two coats of Neoprene are thinned with 10percent

Zylene to insure that the neoprene will soak deeply

into the polyester cloth. Subsequent coats are thinned

but to a lesser degree.

Neoprene is applied with a 3 or 4 inch brush. Use short brush strokes and be sure not to brush the neoprene once it starts to glaze over. That will cause ripples in the surface. Maintain a wet edge and move quickly along the surface. Subsequent coats of neoprene can be applied every 30 minutes or so.

When the skin is removed, the inside hull will receive 2 additional neoprene coats. This is not necessary, but will insure complete saturation, and makes for a better looking job.

Always wear a respirator, and work in a VERY well ventilated area.

Hypalon

After applying neoprene, the deck or hull can be coated with

additional Hypalon to give it a color other than black.

Hypalon cures slower than neoprene and requires a longer

wait between coats. Hypalon stays slightly tacky

for a few weeks. Adding Lacing, zippers, flaps, and deck

rigging can be done in a week or so after coating.

Wait several weeks after coating before removing the skin.

I normally wait a couple of months before folding the skin.

The main advantage of the Polyester/Neoprene/Hypalon skins are their one-piece construction and ease of repair. An additional coat of Neoprene/Hypalon every couple of years will keep it looking like new.

Rub strips can be glued to the keel and chines for added durability.

Skin/Coaming Attachment

On FAP-16, the skin to coaming attachment is accomplished

by wrapping the skin under the baseplate and using snap connectors

(see here for the idea).

On TDY-16, the skin is attached directly under the coaming with machine screws and recessed snap connectors. This is a cleaner installation, but the other method is easier.

Finish

At this stage, all that is left is to install lacing or

zippers, attach the flap, and deck rigging.

The seat is a gunwale mounted sling type similar to that

in FAP-16. A paddling report will be added later.

Contributors to this page: Thomas Yost (TDY), Patrick Poirier (PPR), Gerald Maroske (GUM) and Hendrik Maroske (HHM)